What is the Cause of your Scratched Glass Repair Headache?

Before understanding the cause, you need to understand how tempered and heat treated glass is made. Low quality heat treated glass has become a major source of scratched glass issues in recent years.

Manufacturing Process

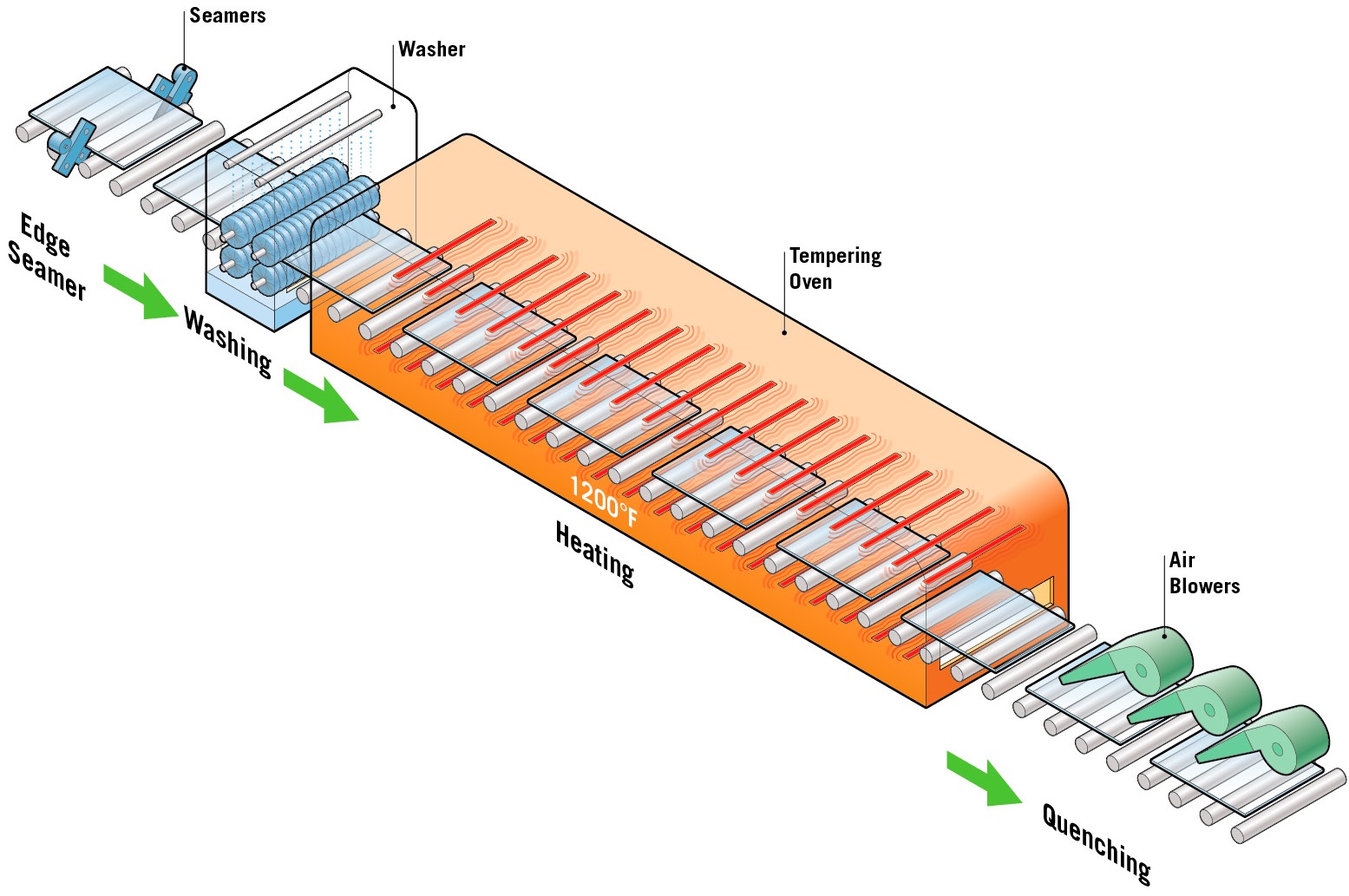

Prior to entering the tempering furnace, annealed glass must first be cut to size (the size of the final product of the glass plate). Heat treated glass can not be cut after it is heat treated because there will be breakage. After cutting the glass to size, the glass plate edges then need to be smoothed using a wheel grinder or sander. This process produces tiny (microscopic) glass fines (like sawdust) that need to be washed off of the glass plate prior to entering the tempering cavity (furnace). Glass washing is an industry standard quality control procedure that glass companies use to maintain a blemish free glass surface after it is heat treated (or tempered). Next, the plate of glass enters the heat treating cavity where it it heated at high temperatures.

If there are any remaining glass fines (like sawdust) remaining on the glass surface (that was not properly washed off) while it is in furnace, then these glass fines can melt enough to become fused to the glass surface. This results in surface defects that should not be present on the final heat treated product. Some glass companies struggle from time to time to maintain their glass washers and their furnace rollers. Furnace rollers can also become contaminated with these glass fines and redeposit these fines back onto the glass even after it has been washed. Furnace rollers also need to be maintained properly and frequently.

If there are any remaining glass fines (like sawdust) remaining on the glass surface (that was not properly washed off) while it is in furnace, then these glass fines can melt enough to become fused to the glass surface. This results in surface defects that should not be present on the final heat treated product. Some glass companies struggle from time to time to maintain their glass washers and their furnace rollers. Furnace rollers can also become contaminated with these glass fines and redeposit these fines back onto the glass even after it has been washed. Furnace rollers also need to be maintained properly and frequently.

After the glass is properly cleaned, it is now ready to enter the tempering (or heat treating) furnace. The glass is heated to 1200 degrees Fahrenheit. Then it is quickly pulled out of the furnace and quenched with cold air to reduce the temperature to 400 – 600 degrees fahrenheit. This is what creates the temper.

How does it become scratched?

During normal cleaning procedures which occur regularly throughout the life of the glass it is possible for low quality glass (glass that is blemished with glass fines as stated above) to become scratched. Window cleaners, janitors, maid services, homeowners, painters, tint film installers, etc. all use standard tools like razor blades to clean glass from time to time as needed. Razor blades are an industry standard tool that is used to efficiently remove paint, stain, tar, sap, bug droppings, hard water stains, stickers, sticker residue, silicone, spores, old tint film, and other materials that can adhere to the glass anytime throughout the life of the glass. During these industry standard cleaning procedures, glass fines (referred to above) can become dislodged and subsequently be dragged across the glass surface while being cleaned. Those glass fines should NOT be present on the glass surface. Industry standard window cleaning tools, including metal razor blades, DO NOT scratch glass. Metal razor blades can be dulled and damaged and still they will NOT scratch normal glass surfaces. The metal is not hard enough to scratch glass alone. However, razor blades (and other tools) are hard enough to dislodge these glass fines (referred to above) and drag them across the glass in between the tool and the glass surface. Since glass scratches glass, the glass fines cause the scratches.

Under a microscope, the cause of glass scratches can be revealed by observing a “comet like” head and a tail to the scratch.

Under a microscope, the cause of glass scratches can be revealed by observing a “comet like” head and a tail to the scratch.

The head of the comet is the original glass fine and the tail of the comet is the resulting scratch that has occurred after the fine (defect) has been dislodged and dragged across the glass.

This should not occur. Builders, Contractors, Maids, Janitors, Tint Film Installers, Window Cleaners, Auto Detailers, and Homeowners should not be held liable for EXPENSIVE REPAIR COSTS!